At the core of the transition to zero-emission vehicles (ZEVs) is the lithium-ion battery, the production of which has raised both environmental and social concerns, particularly around mineral mining. A projected eightfold increase in demand for lithium-ion batteries for road vehicles between 2024 and 2050 illustrates the growing scale of these challenges.

This report explores technologies and policy approaches to support more environmentally and socially responsible EV battery supply chains. The paper explores how strategic sourcing, processing pathways, renewable energy, battery chemistry, and recycling can reduce the carbon footprint of battery production.

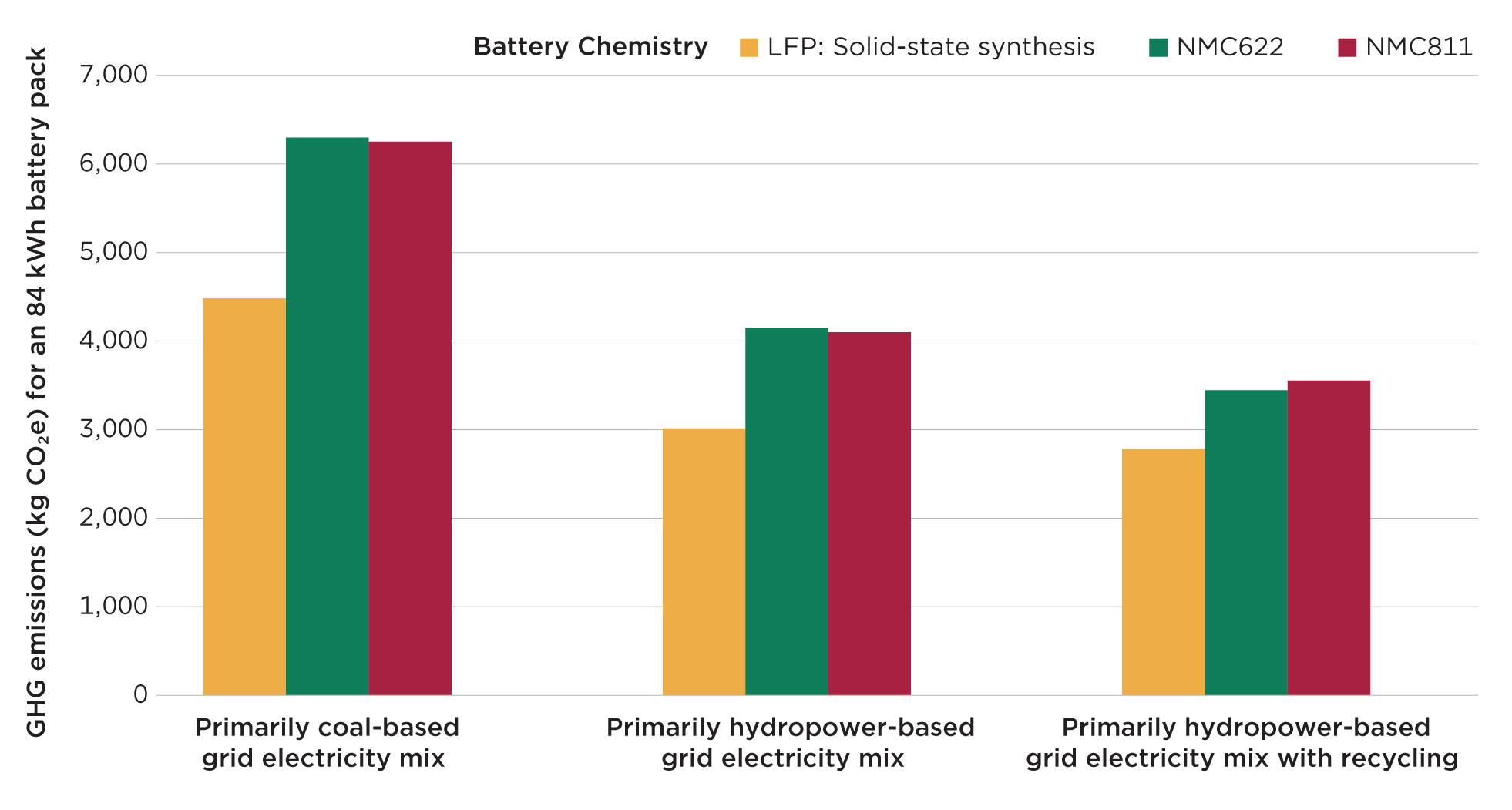

Figure: Life-cycle analysis of battery chemistries produced in different electricity grid scenarios

Note: LFP = lithium iron phosphate; NMC622 = nickel manganese cobalt (6:2:2); NMC811 = nickel manganese

cobalt (8:1:1).

Based on mineral and battery-production GHG modeling assessments and a review of the literature, the report formulates the following key policy considerations:

- Using renewable energy in battery manufacturing and adopting innovative battery technologies present the greatest opportunities to reduce batteries’ embedded GHG emissions. Producing batteries on a renewables-based electricity grid (instead of a high-carbon grid) can lower a battery’s carbon footprint by 30%–40%.

- Mining of key battery materials, like lithium, nickel, and cobalt, account for roughly half of a nickel manganese cobalt battery’s GHG footprint, depending on the source. Although mining practices can be environmentally damaging, deploying responsible practices can reduce this burden.

- Improved battery durability and recycling are among the most effective ways to reduce emissions from the sector. Using recycled materials in the production of a new battery could reduce its carbon footprint by 13%–17%.

- Governments can align battery certification schemes, guidelines, and standards to promote responsible mining and sustainable battery manufacturing at scale. To accomplish this, policymakers might consider integrating these requirements into incentive schemes, type approval, or supply-side regulations.